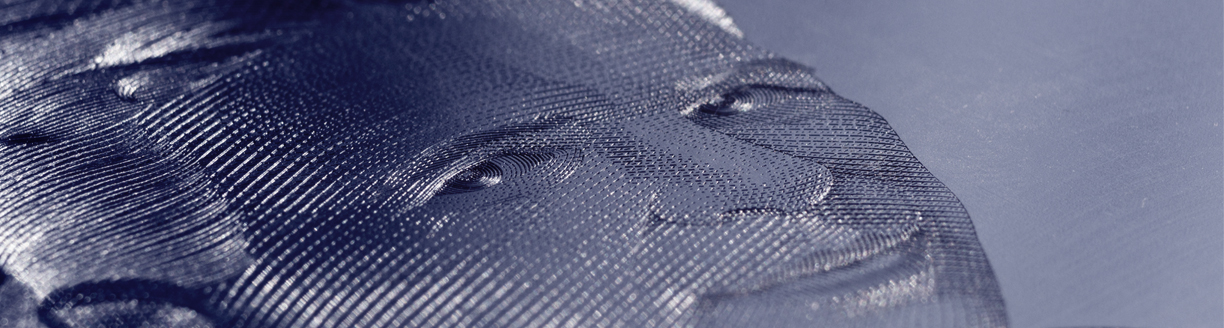

Direct Laser Engraved Steel Plates for Intaglio Printing

In line with today’s latest technologies, Jura has developed a complete set of software and hardware solutions covering the entire Intaglio platemaking process from engraved design to pre-press quality control, laser engraving, and plate quality control. Our pre-press solutions’ continuous development and innovation resulted in a more sophisticated and smoother workflow.

At the Global Currency Forum, Spain, in May 2022 Jura and OeBS together announced the latest development of the Direct Laser Engraved Steel Plates for Intaglio Printing. The new material and printing process meets the highest expectations of Intaglio Printing.

Chemical Free Steel Intaglio Printing Plates by Jura is in line with today’s latest technologies Jura and OeBS together announced the latest development of the Direct Laser Engraved Steel Plates for Intaglio Printing. The new material and printing process meets the highest expectations of Intaglio Printing. The platemaking is a sustainable and environment-friendly process. The new S- DLE® engraved plates are already in production with very positive feedback. S-DLE® is an engraving technic providing full 3D control over the engraving process.

The first printing test on Super Orloff was used with Dummy design, on 600 000 sheets, with no visible plate wear. Printers gave very positive feedback, they were totally pleased with the inking, wiping, and usage in general. As the S-DLE® satisfying the technical constraints, it is now in production. The SDLE plates were coated with PVD chroming, and during production, there was no plate elongation, which was one of their biggest concern. The steel plate post-process is quite the same as it was with the brass, in this way there is no need to change the plate production or the banknote production itself.

DLE® – Digital Laser Engraving – is an engraving technic providing full 3D control over the engraving process including asymmetric line-profiling, multi-level engraving, and precise control of fine-line microtext. The calibration and checks are fully automated, including measuring the plate thickness, laser power, focus, and field correction. There are four types of different engravings, Laura, Hatching, Dithering, Vector Hatching. The Vector Hatching is creating lines similar to the traditional burin-like engraving. The target is to get as close as possible to traditional hand engraving.

This is the third generation of lasers that we use. We started in 2005 with Nano second, since 2012 Pico second laser had been the standard technology. In 2019 Femto laser (ultrashort laser pulses) – which allows engraving in different materials – was fully integrated and become the standard laser.

Direct metal engraving (whether it is brass or steel) plates developed by OeBS and Jura make it possible to print directly or to use the plates as master plates, and by electroforming create nickel printing plates. The new setup covers all possible scenarios for Intaglio plate making starting with different plate sizes (from single original proof size to Super Orloff Intaglio) to direct printing plates, finishing with master plates for the traditional galvanic process.

Currently, the new S- DLE® (Steel Direct Laser Engraving) method has gone through several laboratory and printing tests and fulfilled all the quality checks, it is in production since June 2022.

Jura 2022

Jura 2022